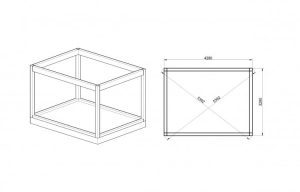

Insulated Office Cube 3×4

The perfect Office Cube for your garden.

Standard Set

- 2 sunscreen walls with glass package;

- 2 Wooden glass walls with glass package;

- 7 standard insulated panel walls;

- Aluminium sliding doors system Reynaers 3 rails;

- Insulated cube frame 3 x 4 m from spruce;

- Roof covered with bitumen weld coating (4 panels);

- Wooden floor (spruce);

Specification

Viking Cube frame from spruce:

insulated floor and roof panels, 4 columns. Insulation – stone wool (50 mm). The frames are made from glue-laminated spruce beams. Frame consists of bottom frame (135 x 90 mm), columns (135 x 135 mm), top frame (135 x 220 mm) and withstands 442 kg/m2 roof load. The floor is made of 146 x 28 mm floorboard. Built with 135 x 90 mm joists.

Aluminium 3-rails sliding door system with locks Reynaers.

The size of the door is 3000 x 2200 mm. Design depth is 50 mm for wings and 120 mm for frames double ground ways and 184 mm for triple ground ways frames. Airtightness: up to 600 Pa (class 4); Water tightness: up to 300 Pa (class 7A); Wind load resistance: up to 1600 Pa (class 4); The thickness of the glass packet: 24 mm; Thermal mould: 1.1 W/(m2 K); System profile frame: 45 mm; Color: metallic/white. Sliding doors in both directions.

Insulated full panel wall.

Panel size is 1000 x 2200 mm; Wall frame 45 x 45 mm, insulation – 50 mm (stone wool), panel covered with inside 96 x 12 mm and outside 145 x 18 mm spruce cladding boards. The thickness of the finished wall segment is 75 mm. A wooden glass wall with glass package. Panel size is 1000 x 2200 mm; Wall frame 75 x 45 mm with glass package of one chamber window. Decorative sunscreen wall with glass package. Wall panel dimensions are (1000 x 2200 mm); Wall frame 75 x 45 mm, horizontal sunscreen wall consists of 18 x 50 mm boards with glass package of one chamber (2 glasses).

The walls, floor and roof of our garden offices are all insulated to lower energy costs. We use stone wool to insulate our garden offices for this reason: fire resilience, thermal properties, acoustic capabilities, durability, aesthetics, water properties, circularity. We include all of the screws, nails and fixings needed to put your garden building together! So there’s no need to worry about the type of screws or length of nails etc you might need to get started, it’s all there in the pack!

Foundation

It is very important to have a proper foundation for your Garden Cube. Therefore we recommend making the foundation according to the sketches here. First of all, a foundation must be prepared according to the landscape and ground conditions. Consult a qualified builder or an engineer to prepare a proper foundation, which fits your location. Make sure to complete the site preparation and the foundation before unpacking and assembling the Garden Cube.

MAINTENANCE

You should not forget that wood is a natural material, it changes move depending on weather conditions. Large and small cracks, colour tone differences and changes, as well as a changing structure of wood are not errors, but a result of wood growing and a feature of wood as a natural material.

Natural wood (not impregnated) becomes greyish after having been left untouched for a while and can be turned blue and become mouldy. You should immediately process them with wood impregnations to protect the wooden details of our produced products.

We definitely recommend that you process the door and windows with a wood impregnation agent, and do it namely both inside and outside, because the doors and windows can become twisted. In general, we recommend for the conclusive finishing a weather protection paint that will protect the wood from moisture and UV radiation after the house is assembled.

Consult a specialist regarding paints suitable for unprocessed softwood and follow the paint manufacturer’s instructions. Your Cube lifetime will be much longer after having properly painted. We recommend that you inspect the house thoroughly once every six months.

What's So Special

Quality

Traditions meets new technologies to create a high quality products.

Experience

More then 10 years of experience

Design

Modern design products for truly exceptional garden.